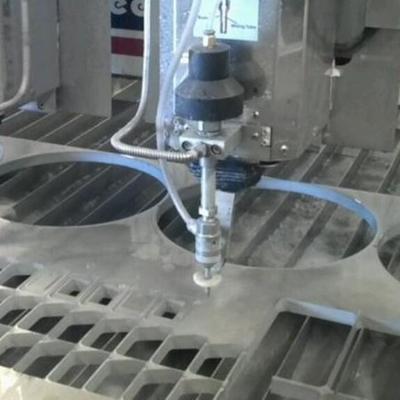

CNC waterjet cutting Abrasive medium Garnet sand 60 mesh HS code 25132000 washed filtration

| Place of Origin | China |

|---|---|

| Brand Name | Honglei |

| Model Number | mesh 60 |

| Minimum Order Quantity | 25 tons |

| Price | FOB Tianjin port USD 170~ 190/ton |

| Packaging Details | 25 kgs / pp-woven bag , then 40 bags in one Jumbo bag ; or 1,000 kgs per Jumbo bag. |

| Delivery Time | 5~8 days for 1x20'FCL |

| Payment Terms | Western Union, T/T, MoneyGram, L/C |

| Supply Ability | 700 tons per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Grit | Mesh 60 | Colour | Dark Red |

|---|---|---|---|

| Usage | CNC Waterject Cutting Abrasive Medium | Bulk Density | 1.8-2.1g/cm3 |

| Chemical Formula | Fe3Al2(SiO4)3 | Crystal System | Isometric |

| Diaphaneity | Translucent To Opaque | Durability | Excellent |

| Fracture | Conchoidal To Uneven | Material | Garnet |

| Melting Point | 1300 | Origin | China |

| Refractive Index | 1.73-1.88 | Shotblast Material | Garnet |

| Specific Gravity | 3.5-4.3 | Streak | White |

| Treatment | None | Usage | Waterject Cutting Sandblasting |

Garnet sand ( HS code : 25132000 ) is an environmentally friendly natural abrasive material,

widely used in sand blasting, CNC high pressure Water-jet cutting , Polishing , Water treatment ,

and Deep oil welling and other special application.

Garnet sand mesh 60 for CNC waterjet cutting abrasive medium :

![]()

![]()

![]()

1. Typical mineral content

| Almandine Garnet | 92-96 % |

| Ilmenite | 1 % |

| Omphacite | 1.5 % |

| Rutile | 0.5 % |

| Quartz | < 0.1 % |

| Hornblende | < 0.5 % |

| Free Silica | < 1 % |

2. Physical Characteristic

| Specific Gravity | 3.8-4.1 |

| Bulk Density | 2.1-2.3g/cm3 |

| Hardness | Mohs 7.0 - 7.5 |

| Chloride | < 25ppm |

| Acid solubility (HCL) | < 1.0% |

| Conductivity | < 8.3µs/cm |

| Melting point | 1300°C |

| Grain shape | Sub angular |

3. Typical Chemical Composition

| Silica SiO2 | 29 % |

| Iron (Fe2O3+FeO) | 31 % |

| Alumina Al2O3 | 17 % |

| Magnesium MgO | 13 % |

| Calcium CaO | 8 % |

| Manganese MnO | < 0.3 % |

| Sodium Oxide Na2O | 0-1 % |

| Titanium Oxide TiO2 | 1.1 % |

Welcome inquiry : Lixuri@vip.163.com

Mobile/ WeChat / WhatsApp : 0086 159 3168 5938